Before roads were built, and before there were settlers, the only overland travel was on foot or by horseback. Early missionaries who travel1ed, carried their belongings in a leather bag, which was made with two pouches. One pouch contained oats for the horse, and the other carried a few artic1es of clothing and some religious books.

Water travel, before 1800, was on bateaux which settlers often used to transport themselves and their goods. Bateaux were a type of boat which were about 30 to 40 feet in length, and six to eight feet in width. They were flat bottomed and could be sailed or rowed. Sometimes they were also poled. A man would walk to the front of the boat, stick his pole in the riverbed, and then walk to the back of the boat, but keeping the pole in place, and thus he pushed the boat along the shore. They were not very fast as it once took one pioneer three months to go from Quebec to the Carrying Place in a bateaux.

A man by the name of Asa Weller had settled at Carrying Place about this time, and he built a track of wooden rails over the narrow isthmus connecting Prince Edward County with the mainland. He hauled boats from the Bay of Quinte to Lake Ontario for a small price. The boats he hauled were quite small, but this included the bateaux.

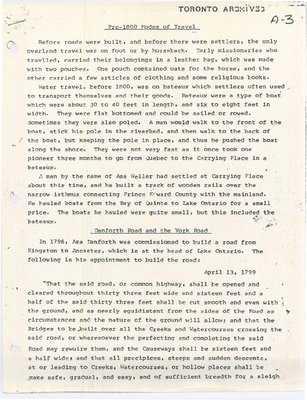

In 1796, Asa Danforth was commissioned to build a road from Kingston to Ancaster, which is at the head of Lake Ontario. The following is his appointment to build the road:

April 13, 1799

"That the said road, or common highway, shall be opened and cleared throughout thirty three feet wide and sixteen feet and a half of the said thirty three feet shall be cut smooth and even with the ground, and as nearly equidistant from the sides of the Road as circumstances and the nature of the ground will allow; and that the Bridges to be bui1t over all the Creeks and Watercourses crossing the said road, or wheresoever the perfecting and completing the said Road may rewuire them, and the Causeways shall be sixteen feet and a half wide; and that aIl precipices, steeps and sudden descents, at or leading to Creeks, Watercourses, or hollow places shall be made safe, gradual, and easy, and of sufficient breadth for a sleigh or carriage to pass. To be paid Twenty Two Dollars and a half for Twenty Chains (a quarter of a mile) as aforesaid.”

From the Ontario Archives

When Danforth was first appointed to build the road, the price was stipulated as thirty dollars per acre, allowing four acres to a mile. However, the price was later reduced to twenty two dollars and fifty cents per acre. As each ten miles was finished and inspected, he would receive one half of his payment. The surveying was done by the government of Canada.

Danforth, in a letter, stated that he wanted each of his good labourers to be allowed a two hundred acre grant, because this would be an incentive for the workers. It was agree to allow this for up to forty workers and also if the workers received a grant of under 1000 acres of land.

The Danforth Road followed the Bay of Quinte from Kingston to Adolphustown where a ferry was used to get over to Prince Edward County. It then went through Picton and Wellington, and then followed the Lake westward. It took three years to build and it was little more than a blazed trail. However, it was the first real entrance into the country by land for the early settlers, and it also provided a link with the outside world for all the settlers in Brighton and vicinity. The old Smithfield Road follows the path that the Danforth Road once followed.

In 1800, the 103 mile section of the road from Toronto to the Trent River was inspected. General fault was found with the width of the bridges, as well as many other problems which included stumps that were still sticking out of the roadbed. In order to meet the specifications, 21,000 5a[?] (equal to $85,000) would have to be spent.

It was not used for long distance travel because carriages and wagons, could not be used on it. People could still only travel on foot or by horseback. Also, there was no demand for the stage coach yet as people preferred to travel by ship.

After the Danforth Road was opened, it fell into a bad state of disrepair where there were no settlements. This was because owners of reserved or unoccupied land were not under obligation to perform statute labour on it. As a result, even in its best condition it became little more than a blazed trail.

In 1811, the road had some repairs performed on it, but they were not very helpful. In 1816, major repairs were again done on the road. It was moved in some places and was renamed the York Road. By Smithfield, the road was moved to the south of the original Danforth Road, as it was in Brighton. The York Road was of corduroy construction. A corduroy road is one in which tree logs are placed side by side over the road bed. Although it was very bumpy, it provided solid footing. However, even the York Road was not very good to travel on.

Captain Basil Hall gave an account of his trip eastward by stage from York in July of 1827. He said the "horrible corduroy roads, filled with deep inky holes which almost swallowed up the front wheels of the stage coach." At times, the stage was "forging like a ship in a headsea," right into holes eighteen inches because of the poor condition of the roads. The Danforth Road, meanwhile had its name changed to Dundas Street in 1830. (For more information see SSP10 and SSP11 in Settlement Patterns Kit.)

Statute Labour

Most roads were maintained by people who lived on the road. Farmers would have to come out for 'a few days each year to work on the roads under the Statute Labour Act. The farmers would work from three to twelve days on the roads, depending on how much they were assessed for. If a farmer did not put in the time, he was charged for it in his [taxes]. One man working for eight hours was considered one day's work while one man, working with a team and wagon for the same amount of time was considered to have worked three days. Each settler was required to build a road across his lot and Pathmasters were appointed to make sure that everyone had worked his three to twelve days on the road.

In 1831, every male on the assessment rolls and who rated under 25 had to do three days work. Property owners rated three to twelve days if they were assessed for £5 to £50. (see D-T 17,24 and D-T 14)

Building Plank Roads

In the 1840s experiments were conducted in building plank roads, because the roads were in such a very bad condition. Private contractors were hired to do the construction, and the specifications for building the plank roads were as follows :

"The boards were to be three inch planks in quality good, sound, plumb-measured, square-edged, and fit for the purpose of scantling four by six inches, sufficient to lay the plank upon, forming two lines of sills.”

The following is the method used to build a road as described by an observer from England.

"The whole breadth of the clearing in the forest is sixty four feet. The roadbed is thirty feet wide, with ditches on either side. The ditches are eight feet wide at the top, and two feet wide at the bottom. They are three feet deep.

The plankway which is sixteen feet wide, is only for use by roughshod horses. There are five rows of sleepers, four inches by six inches laid in the ground, and earth well rammed down on each side of them.

Three inch planks, twelve inches wide, are laid on sleepers secured by six and a half inch by three eighth inch square iron spikes. All road grades must not exceed an elevation of two degrees. All material is of the best pine. Expenses are £500 currency per mile […] 400 currency.

From the Archives of Ontario

The plank roads were described upon completion by a traveler as being smooth as a billiard table. Unfortunately they did not stay that way for long. Some planks wore out sooner than others, if the sleepers on which they were laying sank a little, making then uneven. They were quite satisfactory where the roadbed was sandy, but in the winter, the frost heaved the planks out of place, making costly repairs necessary.

Building Gravel Roads

While Britain was beginning to use better road surfaces, Canada continued to use uncrushed gravel. This resulted in most of the gravel remaining in the centre of the road, or being thrown in the ditch, and in the formation of ruts which caused many wheels to be broken. Very little effort was make to prepare a firm roadbed, with gravel just being dumped on the surface. It was often said, “…Don’t spend so much money on roads because the will be of little use when the railway comes through." This was said in 1840, but at that time, there were only three or four places in all of Canada that could be profitably served by railroads.

The cheapest route for the road should be chosen. Besides construction cost, one should also consider the relative expense of animal strength required to pull a carriage, as shown in the following Tables. (see D-T 9 and D-T 11 in the Document File.)

Formation of the Road

The established width of the road was sixty-six feet. At that time, it was considered too much because of the amount of rise required in the middle of the road to keep it dry. This increased the amount of construction costs and repair.

The first operation is to level the proposed line of the road. Then leveling stakes should be placed every one hundred feet. All deep cutting should be avoided as much as possible because, for example, two cubic yards surface cutting is much cheaper than one cubic yard at a depth of ten to twelve feet.

The height of the centre of the road should be thirteen inches above the level of the edge of the ditch. Five foot wide footpaths on either side of the road should be raised to the same elevation as the centre of the road, with a smooth surface four foot wide at the top.

The cost of forming one mile of road in the forest, taking out roots of trees, and so on, will be from 220 to 280, varying according to the nature of the soil and the strength of timber (to mention a few things). (See D-T 2in Document File.)

Materials for Road Making, and How to Apply Them

The most common road surfacing material used was gravel, which when properly applied, could serve as a good road surface. However, stone, when broken into one and one-half inch cubes, was much better. However, this was also very expensive. In order to prepare gravel for road making, it had to be screened and the pebbles entirely separated from the sand and the clay, and then the larger pebbles ban to be separated from the smaller. Then the larger pebbles had to be broken up into angular portions. Every piece over one and one-half inches had to be broken.

After the road bed was formed, the stone had to be laid so as to make it as impervious as possible to water. This was done by laying down the stone in thin layers and giving each layer time to settle down by the action of wheels on it. The first layer was five inches thick, and after that another five inch layer was required, or two four inch layers were required. The broken stone was never to be dumped on the road all at once, and then levelled. It had to be thrown on by shovel, so as to cause equal consolidation. Therefore it was thought that the job should be done by well trained men.

Granite trap and other crystalline rocks were good road building materials (except if there was too much granite present). Most types of limestone also make good road surfaces, but they did not wear as well as granitic materials, and as a result, they never consolidated nearly as well, although it consolidated faster.

It required 326 toise of broken stone to make one mile of road sixteen feet wide, ten inches thick. One toise equals eight cubic yards. The cost of making a road with limestone for one mile can be broken down as below:

| Road Formation | 250 0 0 |

| 326 toise of stone | |

| @ 12s 6d | 203 15 0 |

| Breaking down | |

| @ 20s | 326 0 0 |

| Laying on stone and finishing road | 1000 0 0 |

| Total cost | 879 15 0 |

The chart shows the price of the road if it was within two miles of a limestone quarry, and the price rose as the distance increased between the quarry and the part of the road being constructed. The greater cost of a granite road was made up for by its endurance.

Road Workers

There were some problems with the men who worked on the road, and often public opinion was against them, as illustrated in the following letter:

"Mr. Editor",

July 8, 1935

Pressing through the township of Otanabee on Wednesday last, on the Rice Lake road, on my way to Peterborough, witnessed a scene which I think cannot be held up to much to public exposure and reprobation. There was the pathmaster and his whole set of people carousing on the roadside over a jar of whiskey, about three o'clock in the afternoon, instead of attending to their work of statute labour…”

There were other problems with the workers also. Men often begged travellers for a bit of money with which to buy whiskey and often they gained their means through intimidation.